Functional Food Systems

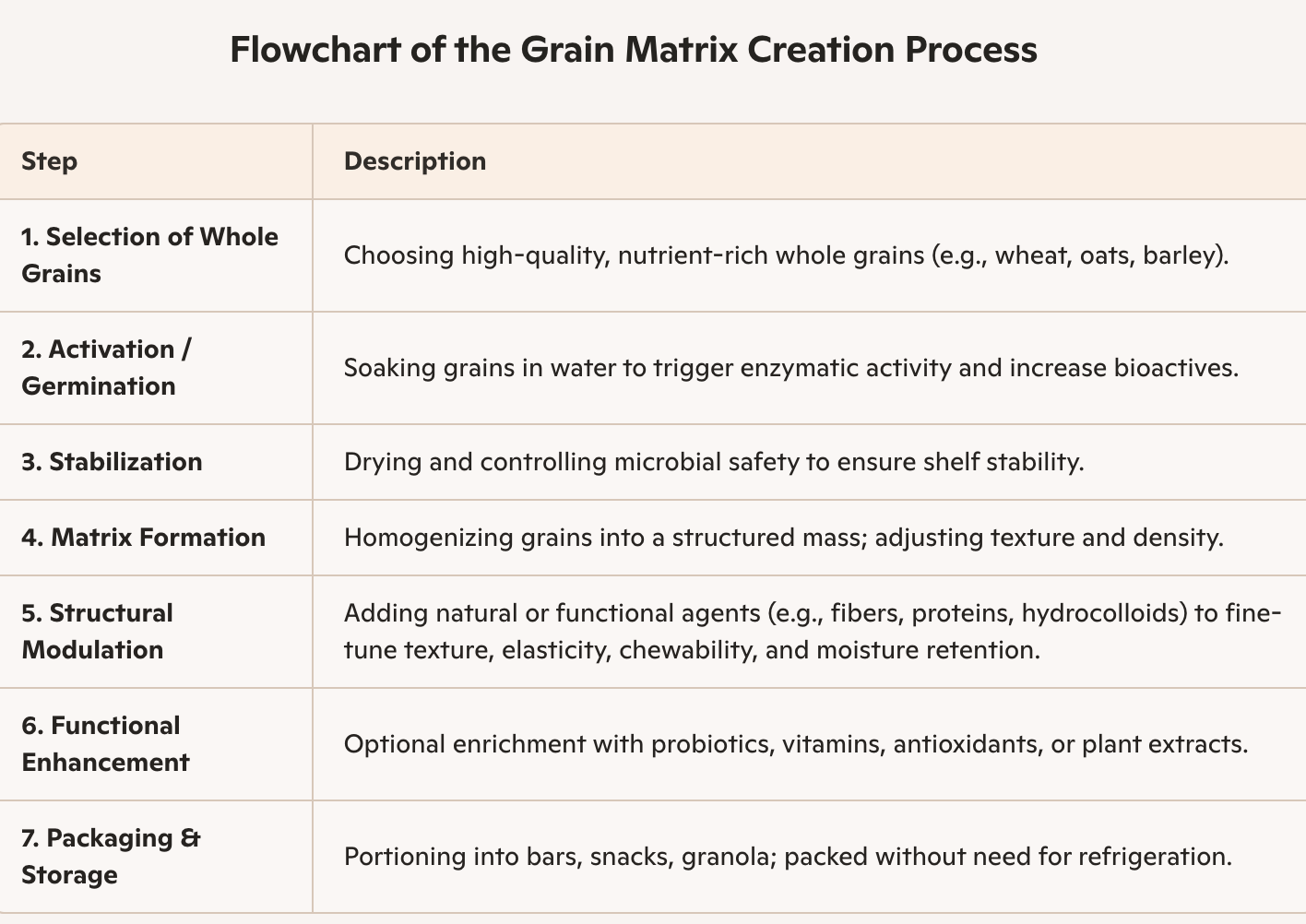

As part of our applied research into bioactive delivery systems, we tested a wide range of candidates — from specialized substrates to neutral organic materials. Through a series of experiments, we identified the optimal format: a stable, fully edible grain-based chewing matrix. Thanks to gentle processing and structural stabilization, the matrix retains key functional compounds — soluble fibers, amino acids, antioxidants, and micronutrients — while allowing precise control over texture and release behavior. Its high nutritional value and versatile properties make it suitable for a wide range of product formats, from functional foods to nutraceutical systems and biodegradable carriers. This is not just an alternative to conventional forms: the technology opens the door to entirely new categories of food products that have never been produced before. The matrix combines biological density, stable texture, and the ability to retain active compounds, making it a foundation for functional nutrition, adaptive supplements, and sustainable innovation. This development not only reduces industrial waste but also merges medicine, nutrition, and environmental engineering into a unified health platform.

The patented elastic matrix technology was originally developed within pharmaceutical research, aimed at controlled delivery of active compounds. During formulation studies, the system demonstrated applicability in food processing—particularly in the transformation of grain-based substrates and secondary fractions into functional edible structures.

The method enables the conversion of selected grain materials into an elastic, chewable matrix suitable for oral use. The resulting material exhibits mechanical stability under mastication and shares key properties with food-grade chewing formats.

Modulation Capabilities of the Matrix

The matrix is a homogenized mass whose sensory properties (density, stability, taste, color, and texture) can be technologically adjusted. This makes it possible to create a wide variety of food products.

Physiological Properties of the Matrix

Matrix from sprouted or soaked grain

Produced through gentle processing.

Retains many active natural substances: beta-glucans, vitamins, minerals, antioxidants.

Starch becomes easily digestible due to natural enzymatic processes.

Its physiological effect is similar to sprouted grains, which are highly valued by health-conscious consumers.

Snacks made from this type of matrix are beneficial and support a balanced diet.

Matrix from flour or separate grain components

Cheaper and simpler to produce.

Contains fewer active nutrients.

Serves perfectly as a carrier for fillers — for example, low-calorie chocolate bars or chewy snacks with pizza flavor.

Functional Application Areas

The matrix can be adapted for the development of various product types:

Grain-based formats with prolonged chewing time

Low-calorie edible structures with tunable texture

Delivery systems for nutraceutical and pharmaceutical compounds

Its food-grade origin and biodegradability allow for precise adjustment of rheological and sensory parameters according to the intended application.

Process Integration and Regulatory Compatibility

The technology is compatible with standard food processing equipment and can be implemented without major modifications to existing production lines. This enables the use of grain side-streams for the creation of value-added products with functional and nutritional relevance.

The composition and safety of resulting products can be tailored to meet international regulatory standards, including those of the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA), ensuring compliance and consumer trust.

Technological Advantages

Utilization of grain-based secondary fractions

Compatibility with existing industrial infrastructure

Adjustable texture, flavor, and nutritional profile

Support for ecologically sustainable processing models

Applicability in nutraceutical and pharmaceutical delivery systems

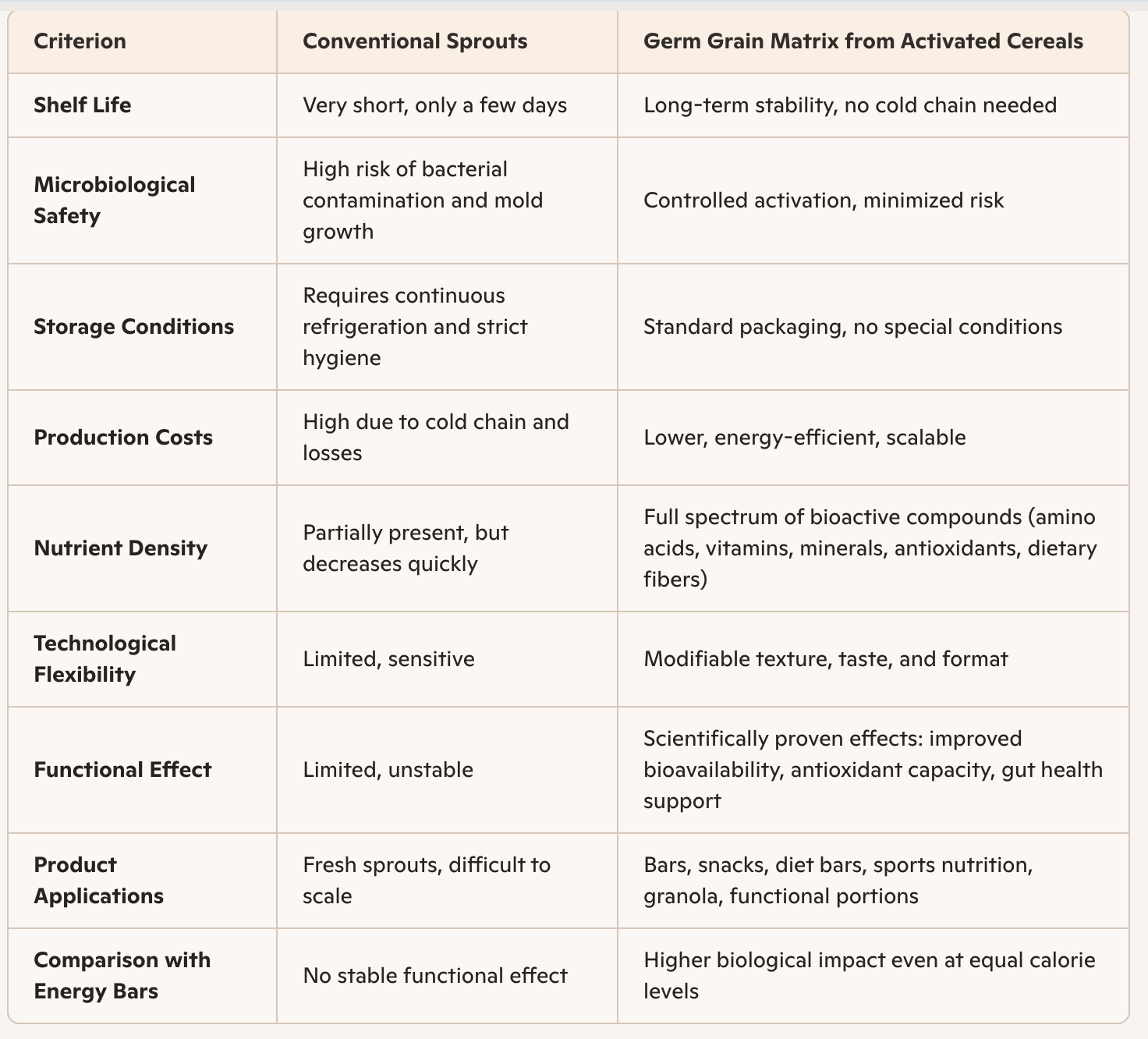

Comparison: Conventional Sprouts vs. Germ Grain Matrix

Bioactive Compounds in Grain Substrates: Functional Potential for Matrix-Based Applications

Scientific overview prepared by Dr. Leo Kacugin

Introduction

During the production of plant-based food matrices, grain substrates undergo hydration, homogenization, and mild thermal treatment. If high-temperature processing is avoided, the resulting mass retains a wide spectrum of bioactive compounds. These components contribute not only to nutritional value but also to the structural and functional integrity of the matrix — enabling applications in functional foods, nutraceuticals, and adaptive delivery formats.

β-Glucans

Soluble fibers present in certain grains (notably barley and oats) remain active under gentle processing. They contribute to matrix viscosity and offer physiological benefits: cholesterol reduction, glycemic control, and immune modulation. Their prebiotic activity supports gut microbiota and enhances metabolic resilience.

Phenolic Compounds

Grain outer layers contain antioxidant phenolics such as ferulic acid, caffeic acid, and avenanthramides (in oats). These molecules exhibit anti-inflammatory and vasoprotective properties. Controlled processing preserves their structure and may increase bioavailability through enzymatic activation.

GABA (Gamma-Aminobutyric Acid)

Formed during fermentation or enzymatic conversion, GABA is a neuroactive compound that supports stress regulation and blood pressure normalization. It can be retained in the matrix under low-temperature conditions, contributing to neuroadaptive product profiles.

Proteins and Amino Acids

Grain-based proteins, including essential amino acids, remain intact under mild processing. Their digestibility improves through enzymatic or microbial activation. These proteins contribute to matrix cohesion and enable the development of protein-rich formats such as spreads, bars, and chewable supplements.

Micronutrients and B Vitamins

Grain substrates retain magnesium, zinc, selenium, and B-complex vitamins when processed without thermal degradation. These nutrients support cellular metabolism, antioxidant defense, and immune function — essential for functional food and supplement applications.

Dietary Fiber and Structural Integrity

Both soluble and insoluble fibers contribute to gut motility and metabolic health. In matrix production, they also serve as structural agents, enhancing texture, elasticity, and moisture retention. This makes the material suitable for chewable formats, baked goods, and nutraceutical carriers.

Application Potential

Grain-based matrices produced under gentle conditions can serve as platforms for: – Functional food products (chewable formats, bars, spreads) – Delivery systems for vitamins, probiotics, and bioactives – Prebiotic supplements and adaptive nutrition – Biodegradable carriers for oral and topical applications

Conclusion

Grain substrates, when processed under controlled, low-temperature conditions, retain a broad spectrum of bioactive compounds. These components support both nutritional and structural functions, enabling the formation of stable, elastic matrices for diverse applications. Smart utilization of grain-derived materials contributes to sustainable innovation, reduced waste, and expanded functionality in plant-based product development.

- Collins FW. "Oat phenolics: avenanthramides, novel polyphenols of oat." Cereal Foods World, 1989.

- Chen CY et al. "Avenanthramides and phenolic acids from oats: structure and antioxidant activity." Journal of Agricultural and Food Chemistry, 2004.

- Tosh SM. "Review of human studies investigating the postprandial blood-glucose lowering ability of oat β-glucan." Food Research International, 2013.

- Sang S et al. "Bioactive compounds in oats: chemistry and health benefits." Journal of Agricultural and Food Chemistry, 2011.

- Shewry PR et al. "Improving the nutritional quality of cereals." Cereal Foods World, 2008.

- Li Y et al. "Fermentation of cereals enhances bioactive compounds and functional properties." Trends in Food Science & Technology, 2020.

- Wang L et al. "Gamma-aminobutyric acid (GABA) in fermented foods: natural occurrence and health effects." Comprehensive Reviews in Food Science and Food Safety, 2018.

- Rebello CJ et al. "Oat consumption and its effects on glycemic control and lipid profile." Nutrition Reviews, 2016.

- Klose C et al. "Utilization of cereal by-products: Nutritional and functional potential of oat pulp." Journal of Cereal Science, 2012.

- Vitaglione P et al. "Whole-grain cereal consumption and health: a review of the evidence." British Journal of Nutrition, 2015.

Biological Benefits of Cereal Beta-Glucans for Human Physiology and Health

1. Introduction

Beta-glucans are soluble polysaccharides composed of β-D-glucose monomers linked by β(1→3) and β(1→4) glycosidic bonds. They are primarily found in the cell walls of cereal grains, especially oats and barley. Over recent decades, beta-glucans have become the subject of extensive research due to their multifaceted positive effects on human health.

2. Physiological Mechanisms of Action

2.1. Effects on the Digestive Tract

Beta-glucans form a viscous gel in the intestinal lumen, slowing gastric emptying and nutrient absorption.

This contributes to prolonged satiety and reduced postprandial glycemia.

2.2. Modulation of Glycemic Response

Slower glucose absorption leads to lower post-meal blood sugar levels.

Clinical studies have shown that consuming 4 g of oat beta-glucans reduces the glycemic index of foods and improves glucose control in patients with metabolic syndrome.

2.3. Lipid Metabolism and Cardiovascular Health

Beta-glucans reduce intestinal cholesterol absorption, lowering total and LDL cholesterol levels.

The mechanism involves binding bile acids and promoting their excretion, which stimulates hepatic synthesis of new bile acids from cholesterol.

Meta-analyses confirm that daily intake of 3 g of beta-glucans can reduce LDL cholesterol by 5–10%.

2.4. Immunomodulatory Effects

Beta-glucans activate innate immunity by interacting with Dectin-1 and CR3 receptors on macrophages and neutrophils.

This enhances phagocytosis, cytokine production, and resistance to infections.

Studies show that beta-glucans can reprogram immune cells, reducing inflammation and improving antiviral defense.

3. Clinical Aspects and Evidence

3.1. Metabolic Syndrome

Including beta-glucans in the diet of patients with metabolic syndrome improves glycemic control, lipid profiles, and gut microbiota composition.

Even low doses (1–2 g/day) positively affect gut flora, increasing bifidobacteria and lactobacilli populations.

3.2. Antitumor Potential

Animal studies suggest that beta-glucans may inhibit tumor growth by activating NK cells and macrophages.

Mechanisms include enhanced antigen presentation and interleukin production (IL-2, IL-12).

3.3. Antioxidant and Anti-inflammatory Activity

Beta-glucans reduce levels of pro-inflammatory cytokines (TNF-α, IL-6) and markers of oxidative stress.

This is particularly beneficial in chronic inflammatory conditions such as atherosclerosis, diabetes, and obesity.

4. Sources and Bioavailability

The highest concentrations of beta-glucans are found in oats (up to 7%) and barley (up to 11%).

Bioavailability depends on grain processing: whole grain products retain more active compounds.

Micronization and fermentation technologies can enhance beta-glucan absorption and efficacy.

5. Conclusion

Cereal-derived beta-glucans are powerful nutraceuticals with proven beneficial effects on human physiological processes. Regular consumption supports metabolic health, strengthens the immune system, and reduces the risk of chronic diseases. Incorporating oats and barley into the diet is a simple and effective strategy for prevention and health maintenance.

References:

EFSA Panel on Dietetic Products, Nutrition and Allergies (2011). Scientific Opinion on the substantiation of health claims related to beta-glucans from oats and barley and maintenance of normal blood cholesterol concentrations. EFSA Journal, 9(6), 2207. https://doi.org/10.2903/j.efsa.2011.2207

Hole, A. S., Rud, I., Grimmer, S., Sigurdsson, S. H., Sahlstrøm, S., & Næs, T. (2012). Improved bioavailability of β-glucans after fermentation of oat-based matrices. Journal of Agricultural and Food Chemistry, 60(25), 6369–6375. https://doi.org/10.1021/jf300410h

Tosh, S. M. (2013). Review of human studies investigating the post-prandial blood-glucose lowering ability of oat and barley food products. Food Research International, 52(1), 437–447. https://doi.org/10.1016/j.foodres.2013.04.001

Wood, P. J. (2007). Cereal β-glucans in diet and health. Journal of Cereal Science, 46(3), 230–238. https://doi.org/10.1016/j.jcs.2007.06.012

Wolever, T. M. S., Tosh, S. M., Gibbs, A. L., Brand-Miller, J., & Wood, P. J. (2010). Physicochemical properties of oat β-glucan influence its ability to reduce serum LDL cholesterol in humans: a randomized clinical trial. European Journal of Clinical Nutrition, 64(8), 837–845. https://doi.org/10.1038/ejcn.2010.178

Beer, M. U., Wood, P. J., Weisz, J., & Fillion, N. (1997). Effect of cooking and storage on the amount and molecular weight of water-soluble β-glucan in oat products. Cereal Chemistry, 74(6), 705–709. https://doi.org/10.1094/CCHEM.1997.74.6.705

Matrix in Food Production

Innovative Grain Matrix – A Foundation for Functional Vegetarian Snacks with Modulated Texture

We've developed a unique grain-based matrix — an elastic, chew-dynamic structure that serves as the foundation for a new generation of food products: functional bars, dietary snacks, and texture-carrying formats. These snacks initially resemble conventional bars, but during chewing, they undergo a two-phase transformation: turning into a soft, elastic, stable mass that can be chewed for an extended time, enhancing the feeling of fullness. This allows for the creation of products with reduced calorie content without compromising taste or enjoyment.

The matrix can be produced from whole grain, flour, or fractionated grain powders. All variants deliver consistent product quality and can be flexibly adapted to different production environments. The technology is energy-efficient, scalable, and compatible with existing food industry equipment — no retrofitting required.

Thanks to its modulated texture and formulation flexibility, the matrix enables the development of new product types — from functional snacks to solutions for appetite control, satiety, and convenient consumption. It's a technologically advanced and sustainable platform for modern food innovation.

For illustrative purposes only. Not medical advice or product endorsement.

International Protection of the Matrix

The matrix we developed is officially registered in both the United States and Europe as six distinct patented inventions. Its modular design allows flexible integration across various segments of the food industry — tailored to specific nutritional, structural, or regulatory requirements.

The production and distribution of products based on the patented matrices without a valid license is prohibited. Qualified potential partners are invited to explore the technology and its applications through our dedicated collaboration channels. For inquiries and licensing agreements, please use the contact section on our website.